Under ballast mats

Materials are a new generation of complex polymer composites that have no analogues in the world.

The advantages of under ballast mats:

- Under ballast mats reduce the load on the subgrade by 2 times, which is especially important for areas with poor load-bearing capacity of soils;

- Under ballast mats prevent vibration transmission to buildings, which causes vibration in walls, floors and ceilings, and, in turn, gener ates «secondary noise» (noise that cannot be eliminated by plastic windows and which cannot be reduced by the use of noise screens);

- Under ballast mats facilitate the reduction of the sanitary protection area boundaries within populated localities;

- Under ballast mats allow heavy trains to pass through the section without any additional measures;

- Under ballast mats help to equalize the load on the ballast layer and the subgrade, thereby extending the maintenance-free service life;

- Under ballast mats reduce the stiffness of the track and turnouts;

- Under ballast mats contribute to tackle the challenge of transition from ballast to ballastless track;

- Under ballast mats withstand an operating temperature range from -60°C to +60°C, which distinguishes it from foreign counterparts.

For bridge decks

- Reduces secondary noise caused by vibration;

- Evenly distributes the loads from the rolling stock to the underlying structures;

- Increases the protective function of the waterproofing layer;

- Reduces the thickness of the ballast layer;

- Reduces track maintenance costs (due to extended maintenance-free operating life);

- Provides isolation from stray current.

For turnouts

For tunnels

Under-sleeper pads

The under sleeper pad is a thin (8-14 mm) layer of elastomeric material that is integrated into the body of the beam. The product has been developed and tested in conjunction with the Technical University of Munich (TUM), it complies with German DIN standards and is patented. The under sleeper pad can be fixed to the sleeper in the factory by integrating it into the concrete. Increasing the contact area of the beam and ballast, lead to:

- Lower contact stresses between beam and ballast;

- Longer service life of the beam;

- Longer ballast service life (increased padding intervals).

Levelling and track stiffness optimisation:

- Reduction of rail wear;

- Levelling of track deflections in transitions (ballast/ballastless, entrances to bridges and crossings);

- Levelling of track deflections along the turnout at the sleeper manufacturing stage.

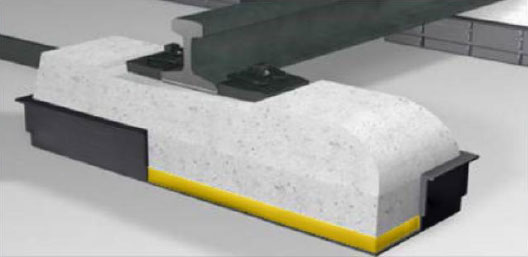

Vibration-damping construction

for tunnels and underground railways

A unique feature of the covers for the blocks is the combination of a functional vibration damping layer of GENER and an elastic waterproofing material of the walls made on the basis of rubber. This system is used on underground and tunnel tracks in a ballastless low-vibration track superstructure. Since the pads are available in any stiffness, this allows to meet a wide variety of requirements for objects of use.

Scope of competence

Provision of qualified management personnel at all stages of project implementation. We offer a range of services for the implementation of railway transport projects with the participation of the world's leading experts.

Development of track elements, mechanisms and equipment in conjunction with the world's leading manufacturers

Contacts

Dubai, United Arab Emirates, Dubai Silicon Oasis, DDP, Building A2